... industry and company news from William Rowland

January 17th 2017

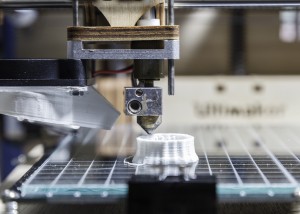

Additive Manufacturing (AM), also known as 3D printing, rapid prototyping or freeform fabrication is a process in which layers of material are used to form three dimensional objects under computer control; opposed to Subtractive Manufacturing such as machining.

Additive Manufacturing (AM), also known as 3D printing, rapid prototyping or freeform fabrication is a process in which layers of material are used to form three dimensional objects under computer control; opposed to Subtractive Manufacturing such as machining.

The use of AM with metal powders is a new and expanding industry, with the ability to now produce complex metal parts rather than just prototypes as before. This is enabling a design revolution in various sectors such as automotive, medical, tooling and energy among others. There are currently a wide range of metal powders being used in AM such as, Steels e.g. 316L, Nickel & Cobalt super alloys, titanium alloys & aluminium alloys. Many more powders are being developed including; copper alloys, magnesium alloys, precious metals and Tungsten alloys.

Using AM over more traditional production methods has the following benefits:

However this new technology also has several limitations:

Share

Contact Us

Please fill in the short form below for any enquiries.

Search

Please fill in the short form below for any enquiries.